OUR SPECIALTY

Since our inception in the year 2000, R&T Reliability Technologies P/L has been developing, refining and implementing visual oil analysis, grease analysis, filter media analysis and micro imaging of contaminates. We specialise in monitoring Large Continuous Manufacturing Plants and Industrial Equipment

With our history of analysing samples from Manufacturing, Mining, and Construction industries we have developed a simple equipment monitoring system with single glance analysis results providing our customers with a ‘Root Cause Analysis Diagnosis’ on every sample.

Through our associate companies we can also provide world class vibration analysis monitoring, metallurgical analysis, scanning electron microscope analysis and root cause failure analysis type services.

OUR AIM

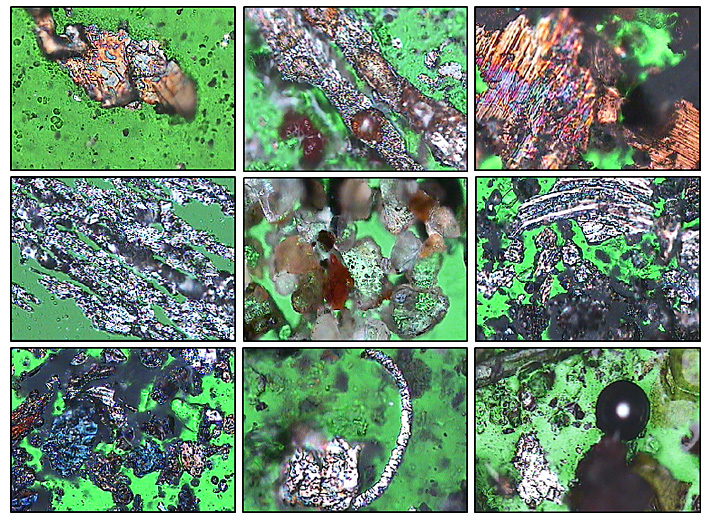

When monitoring critical industrial plant & manufacturing equipment R&T’s recommendations are aimed at operating critical machinery as close to “Zero Wear” as possible. We are able to analyse a sample and identify through microscopic observation contaminates and potential causes of wear. With these observations, R&T provides customers with visual images of the contamination and abnormal wear occurring in the equipment under their care. The showing of wear debris contamination images to the Equipment Maintainer provides an immediate understanding of how the machine is wearing abnormally.

Abnormal Wear Modes taken at 500X Mag

Abnormal Wear Modes taken at 500X Mag ![]() 20µm

20µm

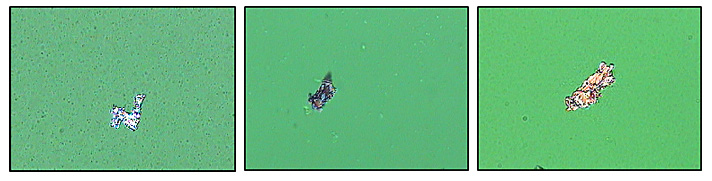

Normal Wear Modes taken at 500X Mag

Normal Wear Modes taken at 500X Mag ![]() 20µm

20µm

Once the remedial advice from the R&T analysis report has been implemented the Equipment Maintainer can also see from following reports the resulting reduction in abnormal wear due to their maintenance work providing 100% reliability plus, feedback and job satisfaction for maintenance staff.

OUR SERVICES

R&T can provide a wide variety of services for our clients including but not limited to:

• AusIndustry Research Provider

• Condition Monitoring large or small manufacturing plants

• Digital Imaging/Photography of Industrial Equipment.

• Dust Analysis

• Flash Point Testing Lubricants, Heat Transfer Fluid

• Grease Analysis

• Heat Transfer Fluid Monitoring

• Metallurgical Analysis

• Oil Analysis

• Oil and Grease Analytical Ferrography

• Oil and Grease Filter Dismantling, Media Extraction and Analysis

• Oil and Grease Wear Debris Analysis

• Oil/Grease Sampling

• Root Cause Failure Analysis

• Scanning Electron Microscope Analysis Oil and Grease Filter Wear Debris

• Scanning Electron Microscope Analysis Oil and Grease Wear Debris

• Varnish Potential in Turbine Fluid, Paper Machine Oils and Hydraulic Systems

• Water Detection

Alongside our analytical services we can provide consultancy for

• Design of Lubrication Systems & Schedules.

• Image recording of Machinery Inventories.

• On Site Contamination Investigation.

• On Site Lube Sample Taking.

• On Site Machine Reliability Improvement.

• On Site Tutorial for oil sampling and contamination control.

• Root Cause Failure Analysis.

R&T understands there are times that our services cannot be utilised and R&T will not persist with any “pressured sale contact” if that situation exists. The introduction to our services can be discussed through contacting the lab though:

E: lab@rttech.com.au P: +61-2-9698-8840(AEST 8am-5pm MON-FRI) Examples of our reports are available for viewing here. Breakdowns of our standard report layouts are available for viewing here.